Item: Specification

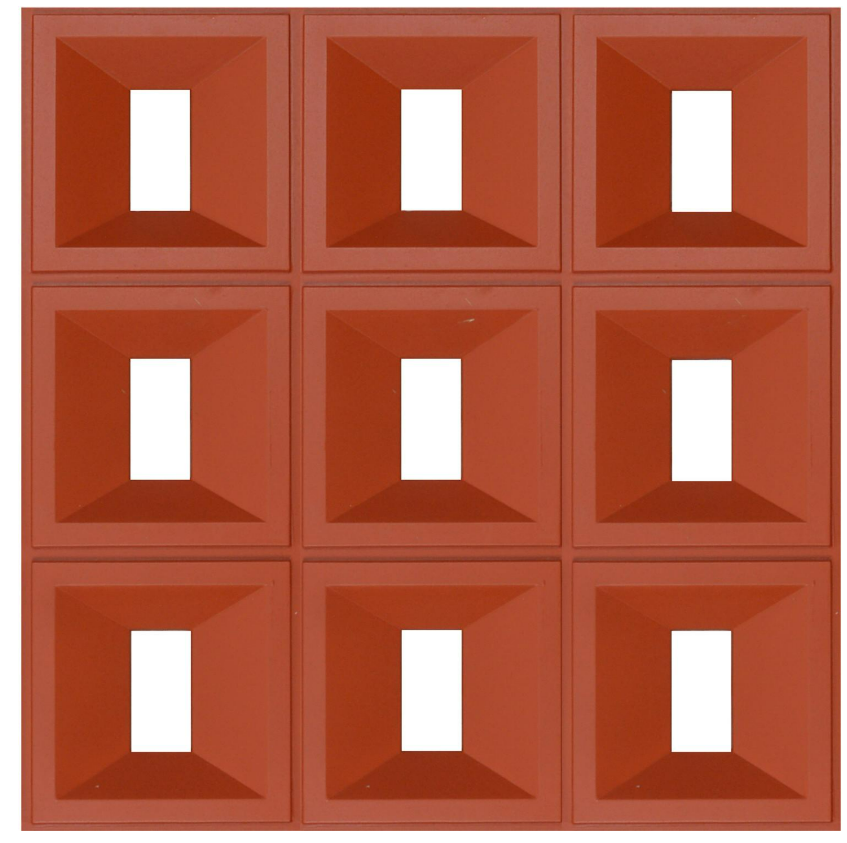

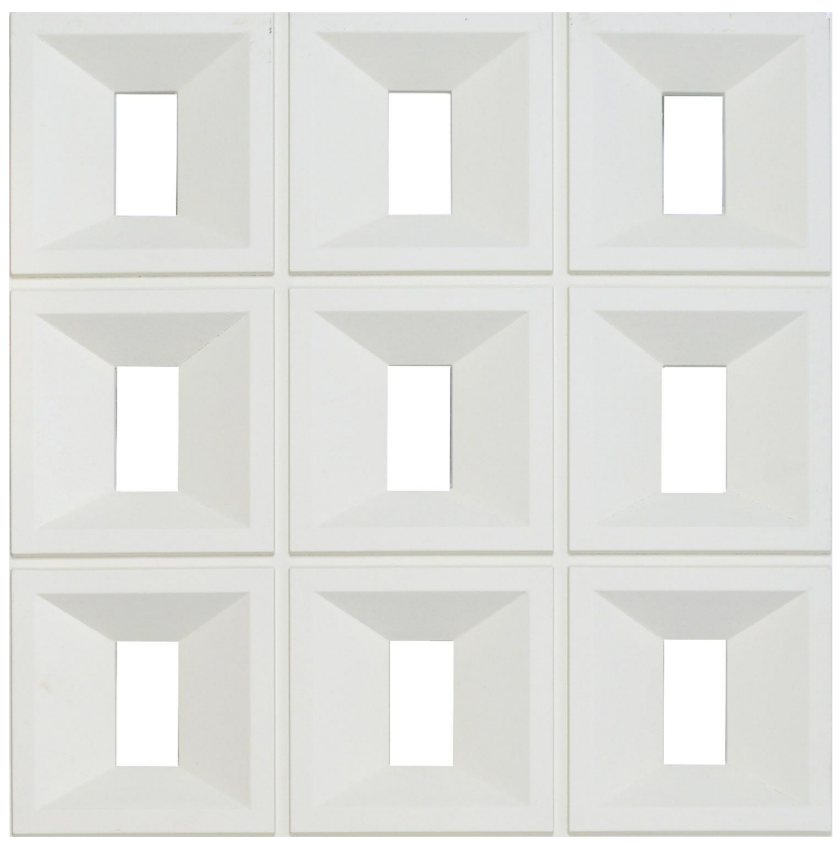

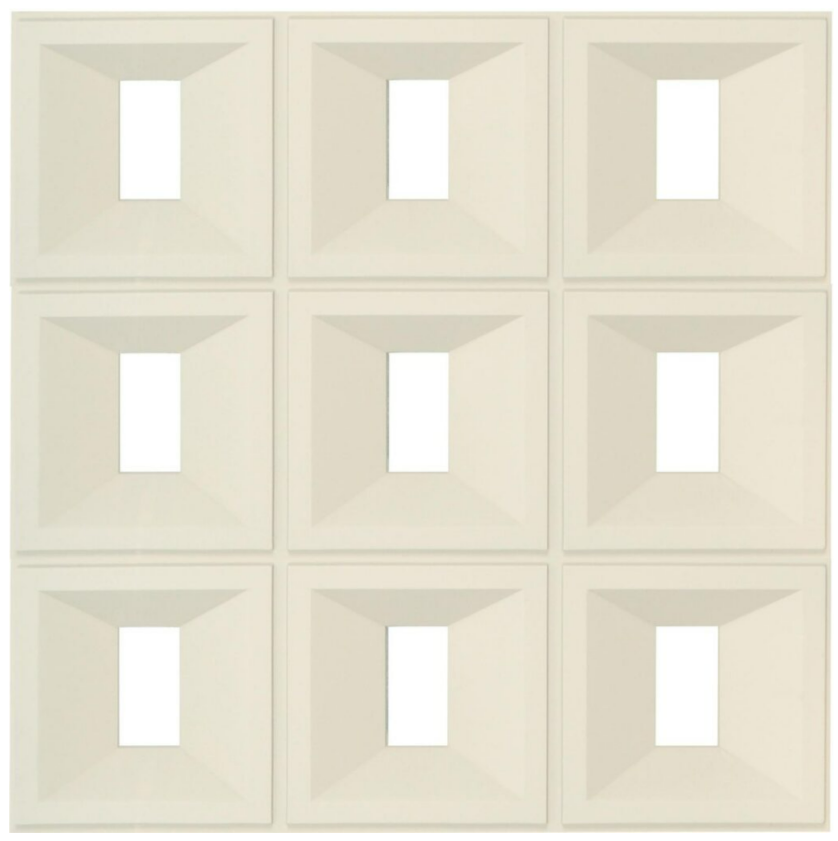

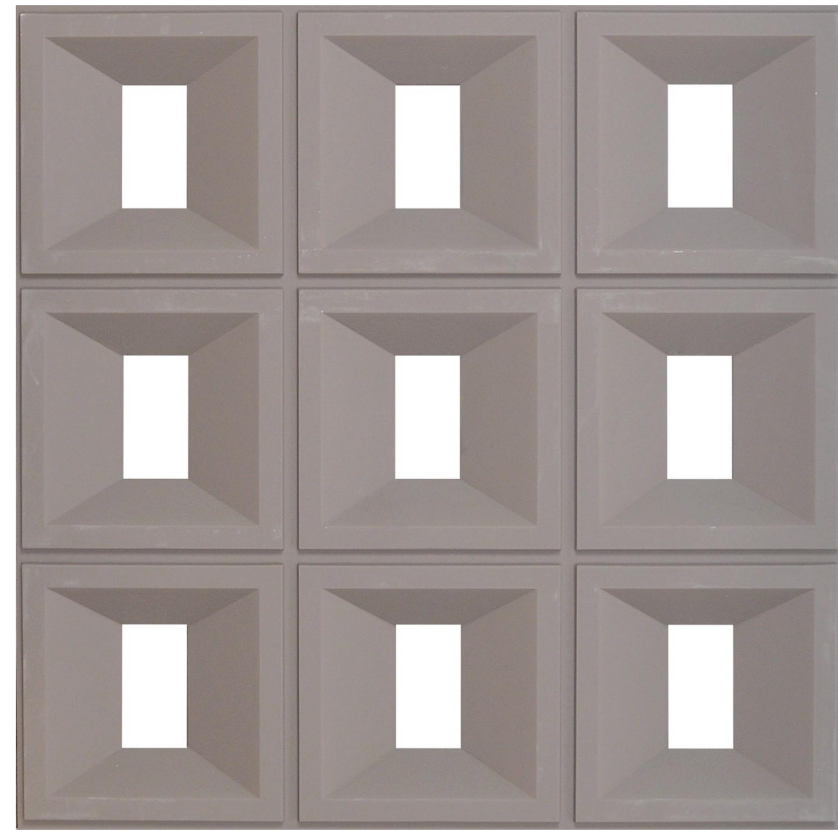

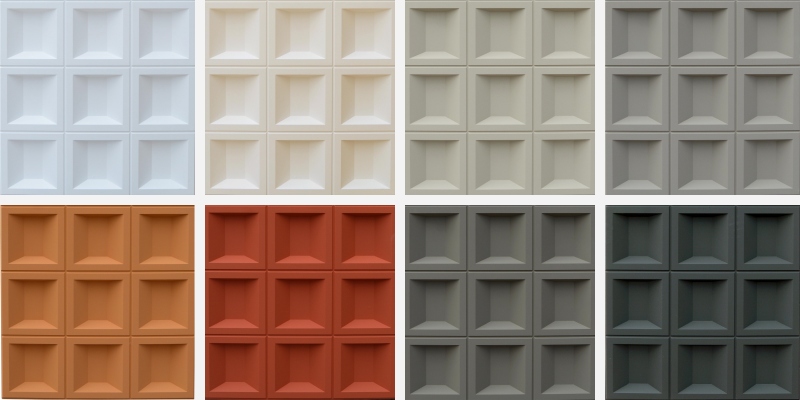

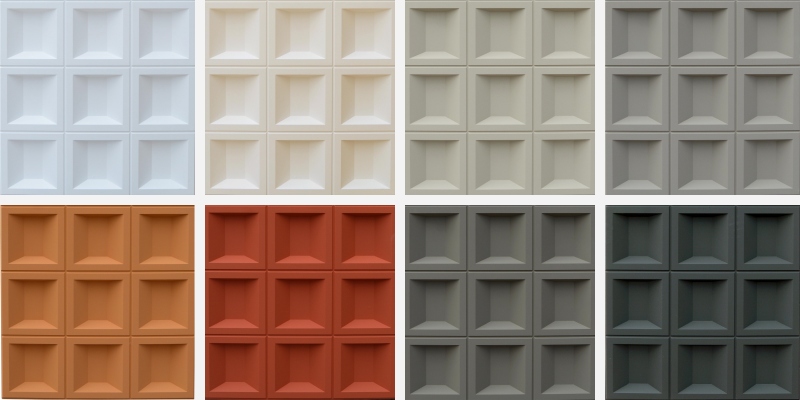

Type: PU Rectangle Nine Grids Shape Panel

Size: 600*1200mm

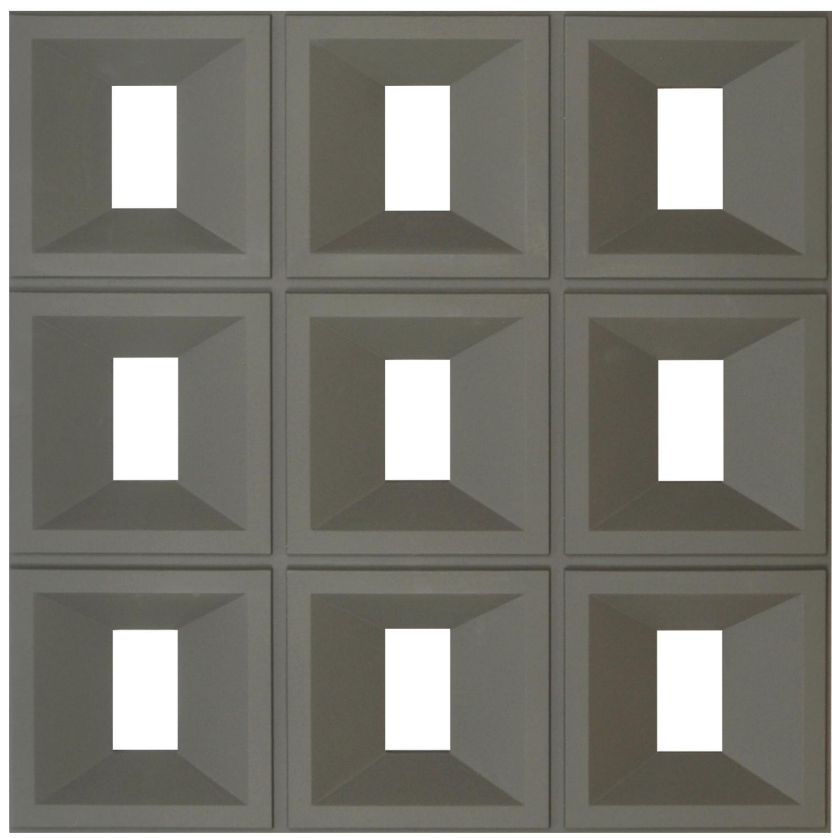

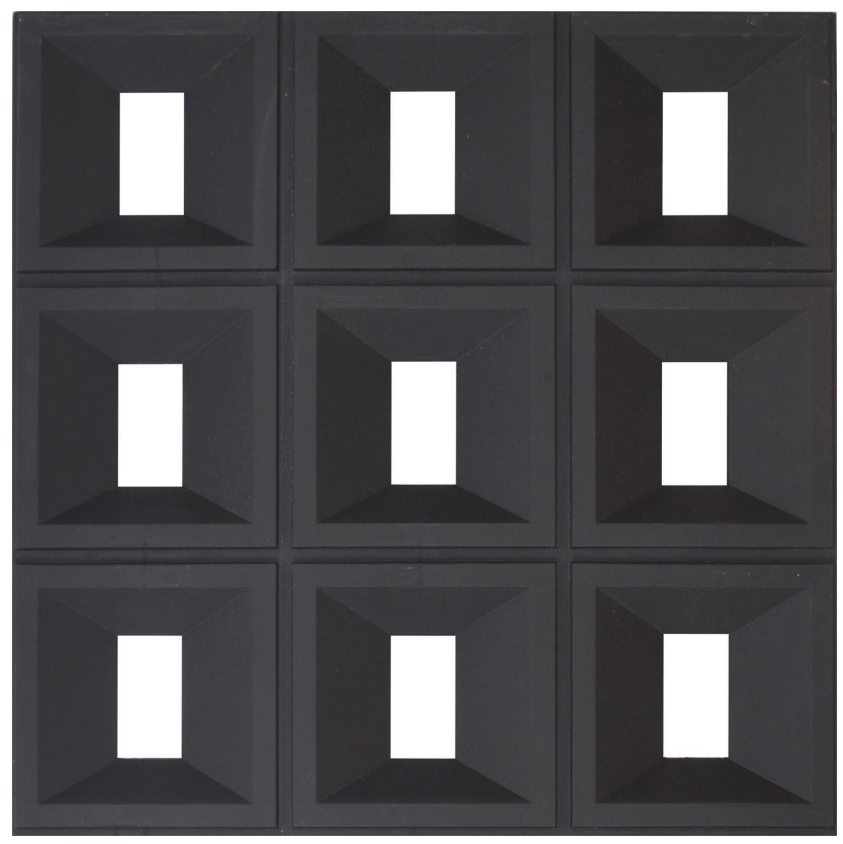

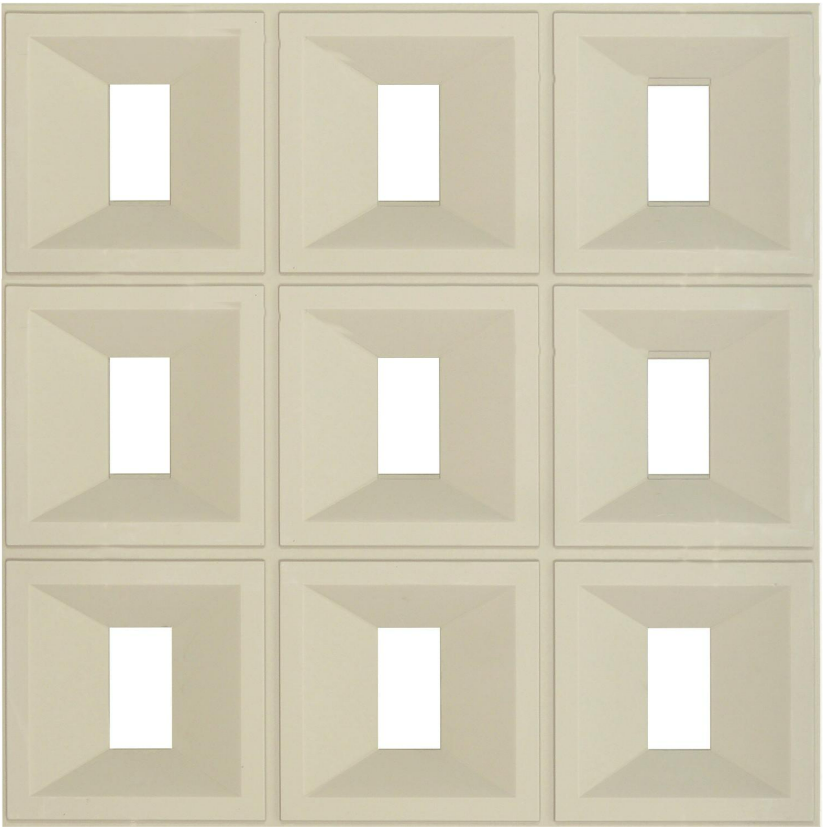

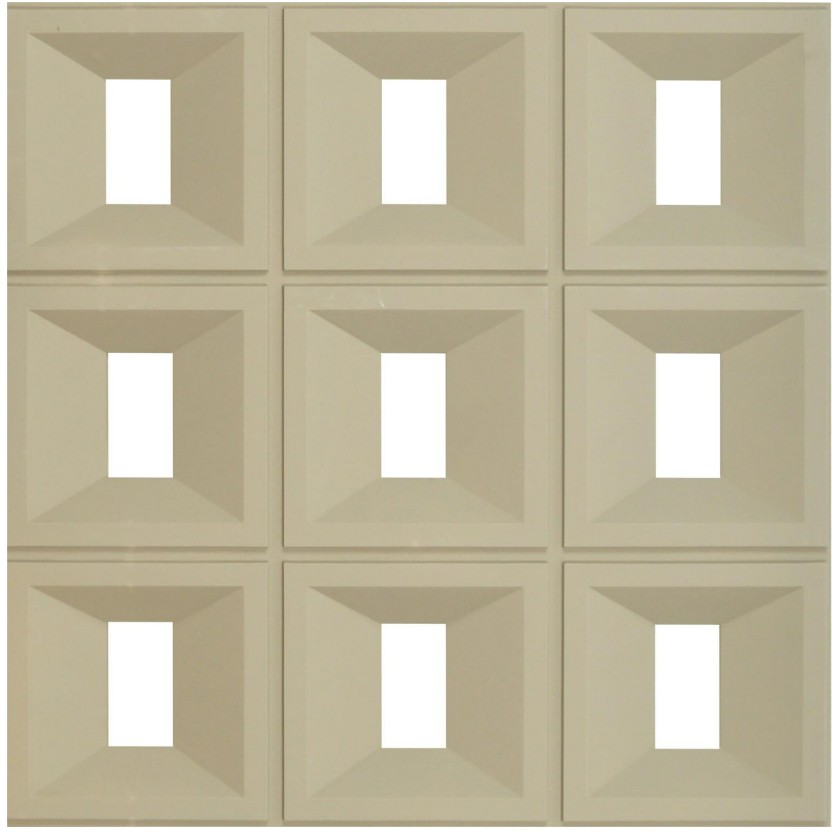

Color: 9 Colors Available

Features: Lightweight/Easy to Transport/Easy to Install/Fireproof/Waterproof

Fireproof: B1

Application: Interior Wall and Exterior Wall

Installation: Glue and Nail

Product Description

– Overview –

PU solid nine-grid wall panel is a kind of decorative wall panel, usually made of polyurethane (PU) solid material, with a special nine-grid design.

These wall panels can be used in interior decoration to provide a unique look and decorative effect.

– Benefits –

+ Solid Material: PU solid nine-grid wall panels are usually made of solid polyurethane material for durability and stability. This solid design gives the wall panels greater structure and weight.

+ Nine-Square Grid Design: PU solid nine-square grid wall panels usually have nine equal-sized square or rectangular areas, between which there can be a flat surface or decoration with textures and patterns. This design style often adds a modern and decorative look to the wall.

+ Colors and Textures: PU solid nine-square grid shape panels are often available in a variety of color and texture options to suit different decorating needs. The choice of colors and textures can be adjusted according to the design scheme of the interior space, creating a harmonious decorative effect.

+ Decorative and Focal Point: PU solid nine-square grid wall panel can be used as a decorative element on the wall to attract the eye and create the focus of a specific area. They are often used in TV background walls, bedside walls, restaurant decorations and other areas to highlight specific decorative effects.

+ Space Division and Definition: PU solid nine-square grid shape panels can also be used for space division, dividing interior spaces into different functional areas without having to use actual partition walls. This is useful in open-plan interior spaces.

Design Effect

PU solid nine-grid wall panels add modernity and decorativeness to interior decoration. This nine-square grid design usually fits well with modern interior design styles, emphasizing modernity and fashion.

The nine-square grid design on the wall panel makes it visually eye-catching, and the unique geometric pattern adds to the decorative nature of the wall. This design can add a modern and artistic feel to the space.

Due to the solid design of PU solid material, these wall panels are highly structural and stable. They are suitable for projects that require stronger support, such as wall decoration in commercial spaces.

PU solid nine-square grid shape panel are generally easy to clean and maintain, requiring just a wipe with a mild detergent and a damp cloth to keep them looking great.

What is PU Stone? The Most Comprehensive PU Stone Introduction

Material collision has always been a visual sensory impact effect pursued by designers. In the past two years, concave-convex stone veneer has appeared in many classic cases, but most people’s choice is to stay away. After all, problems such as raw materials, cost, transportation, and construction are difficult to solve, but there is actually a kind of imitation stone veneer—PU stone, which can be real, has been widely used in many countries. Because many buildings are mainly wooden structures, PU stone is widely used in the decoration of building exterior walls. Well, what kind of material is such a realistic imitation stone veneer—PU stone?

What Are the Characteristics of Pu Stone?

From the perspective of raw materials, PU stone is more like a new cross-border material, applying well-known materials to the decoration materials that restore the real stone. In terms of craftsmanship, the raw materials are pressed through the mold, and at the same time, the color is applied in the mold. Usually, 2-4 sets of molds will be developed for the PU stone of the same appearance. To achieve the effect, the surface is protected by spraying with water-based environmental protection paint for exterior wall waterproofing.

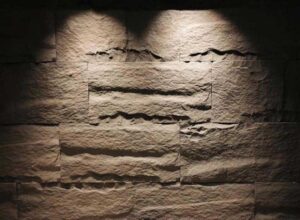

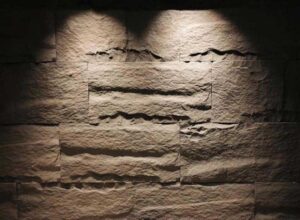

1. Simulation appearance

The product mold of PU stone is finely polished according to the real stone, and with special processing, the appearance of the product is realistic and delicate, which is indistinguishable from the real stone.

2. Long lasting

PU stone has a long service life and saves costs. The PU stone is composed of polymer materials and sprayed with multiple layers of high-strength coatings to make it resistant to acid, sunscreen, and ultraviolet rays, and to last longer.

3. Excellent temperature resistance

The temperature resistance of PU stone is minus 20 degrees – high temperature 120 degrees.

4. Environmentally friendly and pollution-free

Polyurethane products are non-polluting, non-toxic and tasteless. Due to the properties of the raw materials, the synthesis of PU stone does not add too many artificial materials.

5. Keep warm function

PU stone integrates the advantages of an external thermal insulation system and has thermal insulation function.

6. Easy to install

The installation of PU stone does not require high technical requirements for construction personnel, and non-professionals can also construct according to the drawings. PU stone can be used on almost any dry flat substrate indoors, and the direct installation time and the time period required for the entire project are far less than the installation time of traditional cultural stone products. PU stone products are designed with an inner card structure, with tongue edges, full grooves and reserved seams. Most of the installation work does not require caulking, and can be installed directly with screws and gun nails.

7. Novel appearance

The PU style can be adapted to random designs, with strong texture and various shapes, and can be customized according to special requirements.

8. Firm and safe

PU stone adopts prefabricated installation or matching glue to bond to the wall, with high safety factor.

9. Water-proof

PU stone plus a layer of self-developed coating, with waterproof and flame retardant functions.

10. Lightweight

The Construction Process of PU Stone

1. Treatment of the grassroots

Before construction, clean the impurities on the surface of the base of the wall to ensure that the wall is basically flat.

2. Wipe the leveling layer

The leveling layer is to use cement mortar in a ratio of 1:3, and fiber cement board or wood plywood is used as the base for indoor use.

3. Arranging bricks, dividing grids, and elastic lines

In principle, the width of the brick joints is 8mm, and the whole bricks must be used for dividing and arranging bricks. If the whole brick cannot be used, the ash joint should be adjusted. If it cannot be adjusted, the whole brick should be cut.

4. Paste PU stone

The PU stone should be inlaid from bottom to top, and the bonding thickness should be between 4 and 8mm.

5. Pointing

According to the material and depth required by the design, the jointing is carried out horizontally and then vertically to ensure the effect of continuous, straight, smooth, no crack and no hollow.

6. Clean the surface

When the surface is dry and the cement slurry is dry quickly, wipe the whole with dry cotton yarn, and then rinse the paved PU stone with clean water.

English

English

Español

Español